TDS (Technical Data Sheets) SEARCH for TABOREX® product

TABOREX® Compounds

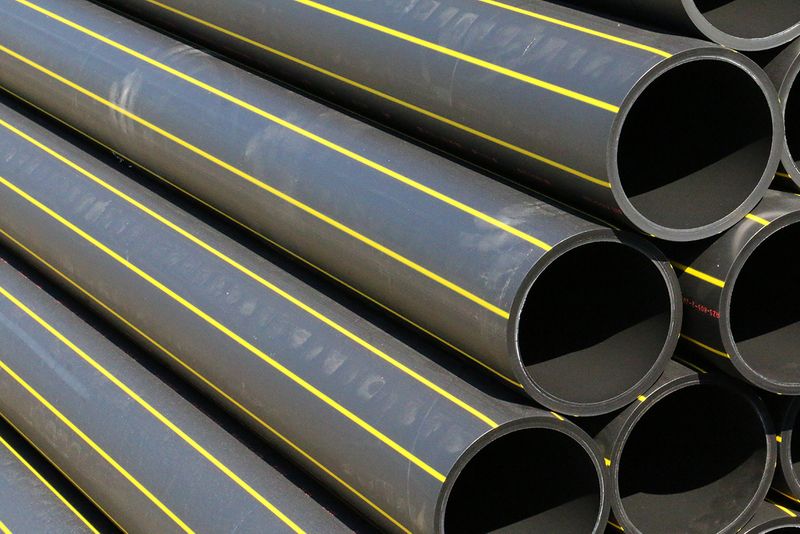

PE-Xb silane cross-linkable polyethylene compounds for pipes, fittings and more.

Discover the advantages of PE-Xb compoundsScopri i vantaggi dei compound PE-Xb

Download Product Catalogue (EN) Scarica il nostro Catalogo Prodotti (IT)

What are you looking for?

Search for a product and download TDS

| Material | Processing type | Application | MFI [g/10 min] | MFI

|

Density

|

Density [g/cm3] | Flexibility | TDS |

|---|---|---|---|---|---|---|---|---|

| TABOREX r-NC 003 | 2 | 2 | 0,55 | 1 | Download | |||

| TABOREX TA 1108 HD | extrusion | sanitary & drinking water pipes / underfloor heating pipes | 2 | 2,7 | 0,943 | 2 | medium | Download |

| TABOREX TA 1132 HD | extrusion | sanitary & drinking water pipes / underfloor heating pipes | 1 | 1,9 | 0,948 | 3 | low | Download |

| TABOREX TA 1155 HD | extrusion | sanitary & drinking water pipes / underfloor heating pipes | 1 | 1 | 0,947 | 3 | low | Download |

| TABOREX TA 1160 CL | extrusion | sanitary & drinking water pipes / underfloor heating pipes | 1 | 1,4

|

0,95 | 3 | low | Download |

| TABOREX TA 1201 HD | extrusion | sanitary & drinking water pipes / underfloor heating pipes | 1 | 1,6 | 0,948 | 3 | low | Download |

| TABOREX TA 1206 HD | rotomoulding | large hollow parts / coating | 20 | 20 | 0,948 | 3 | low | Download |

| TABOREX TA 1211 HD | extrusion | sanitary & drinking water pipes / underfloor heating pipes | 2 | 2,5 | 0,941 | 2 | high | Download |

| TABOREX TA 3004 HD | injection moulding | fittings | 6 | 6,5 | 0,954 | 3 | low | Download |

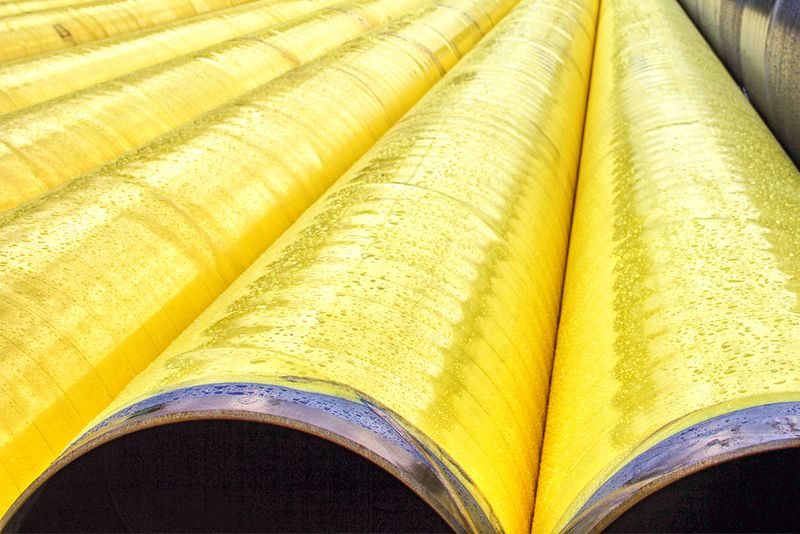

| TABOREX TA 7400 LD | extrusion | metal pipe coating | 9 | 9 | 0,925 | 1 | high | Download |

| Material | Type | Stabilization | MFI [g/10 min] | MFI

|

Reactivity | Colour | TDS |

|---|---|---|---|---|---|---|---|

| TABOREX TA 2111 HD | extrusion | standard AOX | 5 | 5,5 | high | opaque | Download |

| TABOREX TA 2120 HD | extrusion | standard AOX | 8 | 8,5 | medium | opaque | Download |

| TABOREX TA 2131 HD | extrusion | standard AOX | 5 | 5 | high | opaque | Download |

| TABOREX TA 2142 HD | extrusion | standard AOX | 5 | 5 | medium | opaque | Download |

| TABOREX TA 2143 HD | extrusion | standard AOX / metal deactivator | 5 | 5,5 | high | opaque | Download |

| TABOREX TA 2147 HD | extrusion | standard AOX / metal deactivator | 9 | 9 | high | opaque | Download |

| TABOREX TA 2155 HD | extrusion | standard AOX | 8 | 8,3 | medium | opaque | Download |

| TABOREX TA 2160 UV | extrusion | high AOX / UV / metal deactivator | 11 | 11,8 | medium | opaque | Download |

| TABOREX TA 2170 CL | extrusion | chlorine resistant (CL) | 9 | 9 | medium | opaque | Download |

| TABOREX TA 2171 PW | extrusion | standard AOX | 9 | 9 | high | opaque | Download |

| TABOREX TA 2174 HD | extrusion | standard AOX | 8 | 8 | low | opaque | Download |

| TABOREX TA 2175 CL | extrusion | chlorine resistant (CL) | 9 | 9 | high | opaque | Download |

| TABOREX TA 2343 HD | extrusion | standard AOX / UV | 2 | 2,5 | low | black | Download |

| TABOREX TA 2350 HD | extrusion | standard AOX | 8 | 8,6 | high | black | Download |

| TABOREX TA 2363 HD | extrusion | standard AOX | 9 | 9,2 | medium | yellow | Download |

| TABOREX TA 2385 HD | extrusion | standard AOX | 8 | 8,7 | low | white | Download |

| TABOREX TA 2410 CL | extrusion | high AOX / UV / metal deactivator | 9 | 9 | high | red | Download |

| TABOREX TA 2411 CL | extrusion | high AOX / UV / metal deactivator | 12 | 12,9 | high | blue | Download |

| TABOREX TA 2412 CL | extrusion | high AOX / UV / metal deactivator | 12 | 12,9 | high | white | Download |

| TABOREX TA 8030 LD | extrusion | standard AOX / metal deactivator | 4 | 4,5 | low | opaque | Download |

Contact us

Strategic sales

Are you interested in any of our products? Do you need to find the right material for your product? Contact our sales team.

Technical customer support

Do you need technical assistance? Is there something wrong with the material? Contact our specialists.